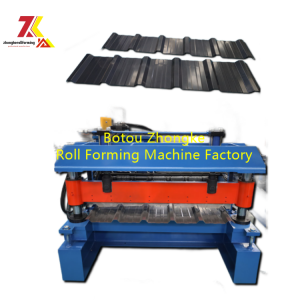

ZKRFM 36 Inch Trapezoidal Sheet Tile Making Machinery Roll Forming Machine

| item | value |

| - | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

| - | None |

| - | New |

| - | Tile Forming Machine |

| - | Colored Steel |

| - | ROOF |

| - | 15 m/min |

| - | Botou City |

| - | ZKRFM |

| - | 380V or as the customer's requirements |

| - | 9500*1300*1000mm |

| - | 8000kg |

| - | 1.5 years |

| - | Easy to Operate |

| - | 0.3-0.8mm |

| - | 1220mm |

| - | Provided |

| - | Provided |

| - | New Product 2024 |

| - | 1.5 years |

| - | Pressure vessel, Motor, Bearing, Gear, Pump, Gearbox, Engine, PLC |

Selling Point

1.Easy to Operate: The ZKRFM 36" Trapezoidal Sheet Roll Forming Machine is designed for simplicity and efficiency, allowing users to effortlessly operate the machinery with minimal training or experience.

2.Versatile Applicability: This tile-making machinery can be used across various industries, including hotels, garment shops, building material shops, manufacturing plants, machinery repair shops, food & beverage factories, farms, restaurants, home use, retail, food shops, printing shops, construction works, energy & mining, and advertising companies.

3.High Production Capacity: The ZKRFM 36" Trapezoidal Sheet Roll Forming Machine boasts a production capacity of 15 meters per minute, ensuring a rapid and efficient manufacturing process.

4.Durable Materials: The machine's roller material is made of 45# forge steel, coated with chrome, providing longevity and resistance to wear and tear. The shaft material is also 45# forge steel, chrome-plated for added strength.

5.Comprehensive Warranty: The product comes with a 1.5-year warranty on core components, including the pressure vessel, motor, bearing, gear, pump, gearbox, engine, and PLC. This extensive warranty coverage ensures peace of mind for users and provides assurance in the product's quality and performance.

Detailed Images

Feed Platform

The Square Tube Feed Platform is an essential component of our roll forming machine, designed to ensure precise material feeding and alignment, guaranteeing seamless and accurate production processes.

Chrome treated shaft and wheel

The Chrome-treated shaft and wheel for our roll forming machine ensure exceptional durability and smooth operation. The chrome coating enhances resistance to wear and corrosion, prolonging the machine's lifespan and maintaining consistent performance.

Guide post cutting head

The Guide Post Cutting Head is an essential component for roll forming machines, ensuring precise and clean cuts. Its advanced design guarantees accuracy, efficiency, and seamless production.

Production Flow

FAQ

1. What is your guarantee period?

Guaranteed against malfunctions due to manufacturing defects for 12 months from the date of loading.

2. Do you provide training for my workers?

The machine has been installed and tested well before shipping. It is easy to operate.

Normally speaking, our customer follows the instruction book and can operate the machine well.?

You can also come to our factory to check the machine and learn how to operate it before shipping. It only needs 2 hours and you can operate well.

3. I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

If you need us to send engineers to your factory, you will pay for the travel expense such as visas, round tickets, hotels, and food Salary of 80 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take care of his safety.

4. What is included in the machine?

The process for work: decoiler→feeding→roll forming→measuring length→cutting to length→product to stand

The whole line includes 1, a manual decoiler, 2, roll forming machine, 3 product stand and 4 spare parts list.