ZKRFM Double Layer Machine Double Layer Forming Machine Double Layer Roll Forming Machine

Title: Efficiency of Double Layer Roll Forming Machines in Manufacturing

In manufacturing, efficiency is key. This is why double-layer roll forming machines are becoming more and more popular among manufacturers. These machines are designed to create two different profiles from the same base material, making them a versatile and cost-effective solution for companies looking to increase productivity.

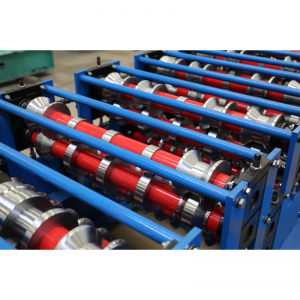

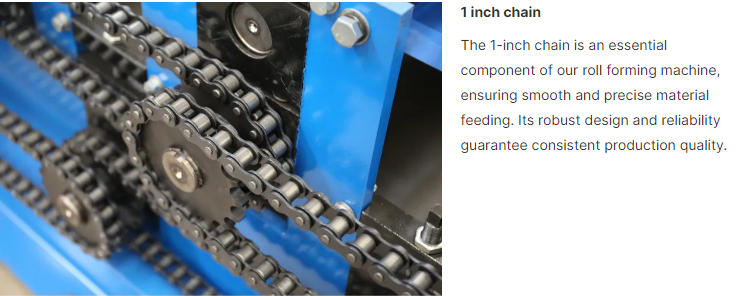

Double-layer roll forming machines work by passing a continuous strip of metal through a series of rollers, gradually shaping it into the desired profile. The machine is equipped with two sets of rollers that can create two different profiles simultaneously. This means manufacturers can produce double the quantity of products in the same amount of time, ultimately increasing output and reducing production costs.

One of the main advantages of using a double layer roll forming machine is its efficiency. By producing two different profiles simultaneously, manufacturers can save time and labor, ultimately maximizing production capacity. This is especially beneficial for companies with high production needs or tight deadlines.

Another benefit of using a double layer roll former is its versatility. These machines can create a variety of profiles, making them suitable for a variety of industries and applications. Whether you need to manufacture roof shingles, wall cladding, or even automotive parts, a double-layer roll forming machine can get the job done with ease.

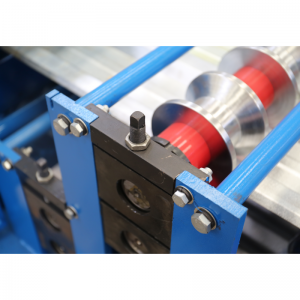

Additionally, double layer roll forming machines are designed to deliver high quality results. The precision and accuracy of these machines ensures that the profiles produced meet the required specifications, providing customers with a consistent, reliable product.

In summary, a two-layer roll forming machine is a valuable asset for manufacturers looking to increase efficiency and productivity. By creating two different profiles simultaneously, these machines can help companies meet their production needs and stay ahead of the competitive market. With their versatility and high-quality results, double-layer roll forming machines prove to be a wise investment for modern manufacturers.