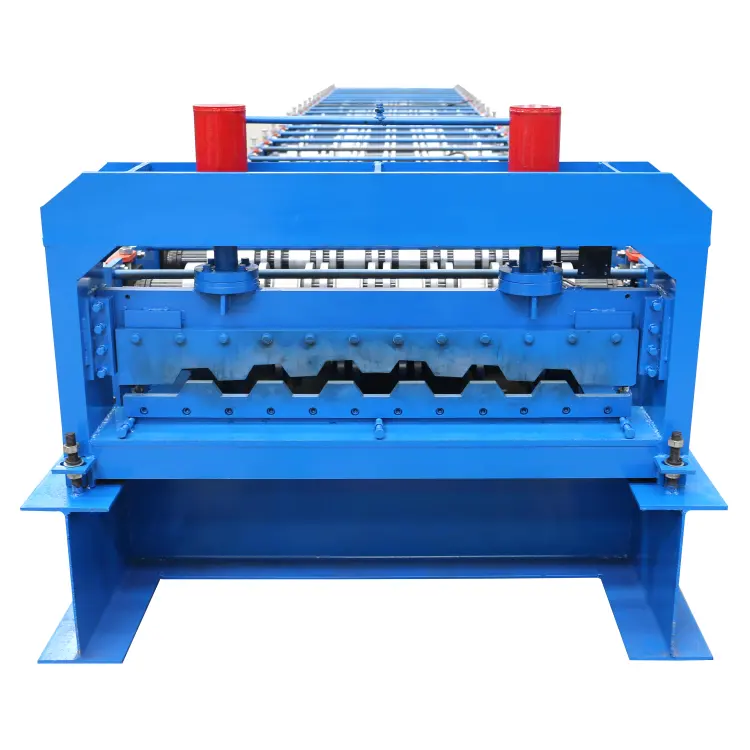

Car Body Panels Forming Stamping Machine

| Formed Material | PPGI,GI,AI | Thickness:0.3-0.8 mm |

| Decoiler | Hydraulic decoiler | Manual decoiler(will give you as free) |

| Main body | Roller station | 12rows(As your requirement) |

| Diameter of shaft | 70mm solid shaft | |

| Material of rollers | 45#, hard chrome plated on the surface | |

| Machine body frame | 300H steel | |

| Drive | Double Chain transmission | |

| Dimension(L*W*H) | About 7.5*1.15*1.51m | |

| Weight | About 7.5ton | |

| Cutter | Automatic | cr12mov material, no scratches, no deformation |

| Power | Main Power | 22KW or As your requirement |

| Voltage | 380V 50Hz 3Phase | As your requirement |

| Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| Forming Speed | 15-20m/min | The speed depends on the shape of the tile and the thickness of the material.

|

PRODUCT LINE

OUR CUSTOMERS

Our products are sold to many countries and regions all over theworld, and we have established long-term cooperative relations with clients!

PACKAGING & LOGISTICS

FAQ

Q1: How to play order?

A1:Inquiry---Confirm the profile drawings and price ---Confirm Thepl---Arrange the deposit or L/C---Then ok

Q2: How to visit our company?

A2: Fly to Beijing airport: By high speed train from Beijing Nan to Cangzhou Xi(1 hour),then we will pick you up.

Fly to Shanghai Hongqiao airport:By high speed train from Shanghai Hongqiao to Cangzhou Xi(4 hour),then we will pick you up.

Q3: Are you manufacturer or trading company?

A3: We are manufacturer and trading company .

Q4: Do you provide installing and training overseas?

A4: Overseas machine install and worker training services are optional.

Q5: How is your after sales support?

A5: We provide technical support on line as well as overseas services by skillful technicians.

Q6: How does your factory do regarding quality control?

A6: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

Q7: How can I trust you that machines pasted testing running before shipping?

A7: (1) We record the testing video for your reference. Or,

(2) We welcome your visit us and test machine by yourself in our factory

Q8: Do you sell only standard machines?

A8: No. Most machines are customized.

Q9: Will you deliver the right goods as ordered? How can I trust you?

A9: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided).