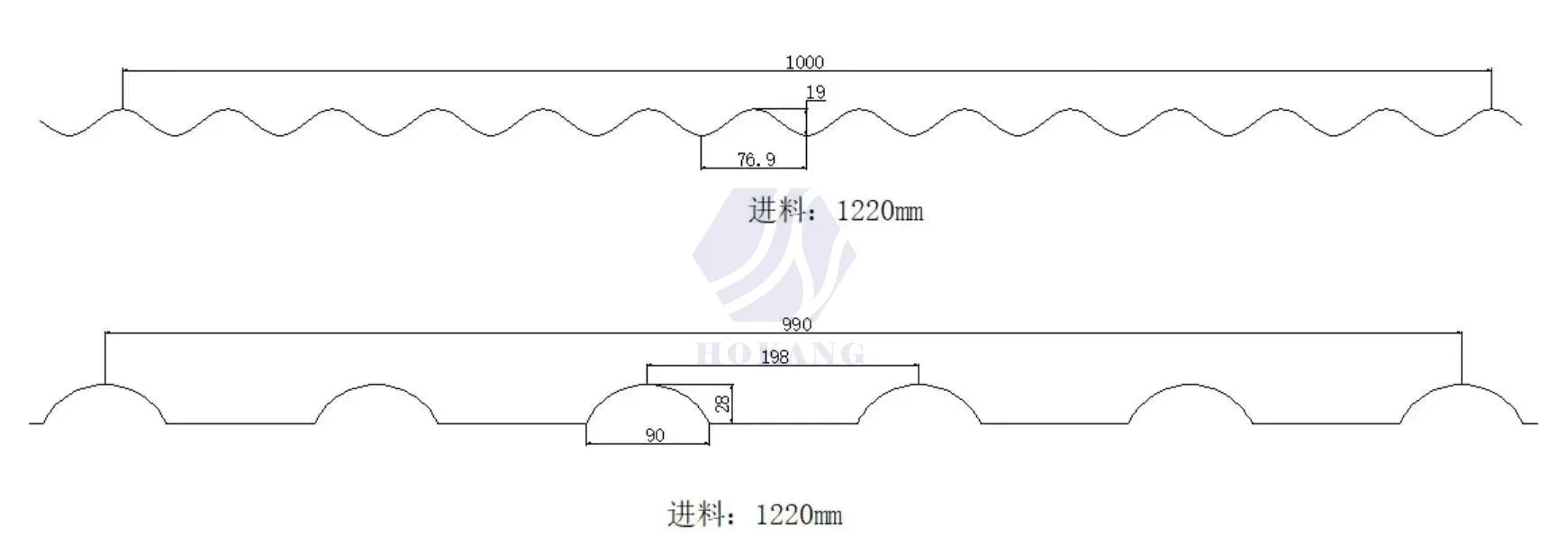

Hydraulic Automatic Cold Roll Forming Machine Double Layers Roofing Panel Roll Making Machine

Glazed Corrugated Tile Roof Roll Forming Machine 800+850mm

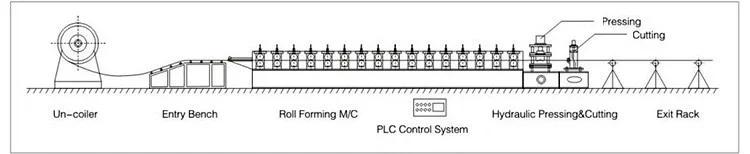

Roll forming machine is a machine composed of feeding, forming and post-forming cutting. Its color plate appearance is smooth and beautiful, uniform paint pattern, high strength and durable. It is widely used in industrial and civil buildings, such as factory buildings, warehouses, stadiums, exhibition halls, theaters and other rooms and walls.

Color profiled steel plate is a profiled plate that adopts color coating steel plate and is rolled and cold-formed into various wave shapes. It is suitable for industrial and civil buildings, warehouse special buildings, and large-span steel structure

houses. Wall decoration, etc., has the characteristics of light weight, high strength, rich color, convenient and fast construction, earthquake resistance, fire resistance, rain resistance, long life, and maintenance-free. It has been widely promoted and applied.

Specification

| Item | Description |

| Applicable materials | Colored glazed steel |

| Feeding width | 1000-1200mm |

| Effective width | 800-1000mm |

| Material thickness | 0.3-0.8mm |

| Number of rollers | 13rows/9 roller |

| Frame size | 350H section steel (national standard) |

| Middle plate thickness | 16mm |

| Roller material | 45 # steel |

| Roller diameter | Roller diameter |

| Drive servo motor | 5.5KW |

| Oil pump power | 4KW(Large box + cooling air box) |

| Tool material | Cr12 |

| Voltage | 380v,50hz,3 phase |

| Cutting accuracy | ±2 mm |

| PLC panel | touch screen electric control cabinet |

| Outside dimension | L*W*H=6500mm*1500mm*150mm |

| Forming speed | Glazed tile 2m/min Common 10-15m/min |

Forming Roller Of Roll Forming Machine

The roller of the glazed tile forming machine has high utilization rate, high strength, high degree of production automation, and is durable. This model of machine adopts the 9-13 roller design, which can better press the required shape. Compared with fewer rollers, the effect of wheels will be better.

Decoiler of roll forming machine

Roof sheet make machine load parts, decoiler loading frame we can offer different type can choose. standard type are manual,also can choose electric loading frame or hydraulic loading frame. This loading frame decoiler also can use in other type machine, customer can buy it alone.

PLC Control System Of Roll Forming Machine

The control system adopts the combination of touch screen and button to control, which is more convenient. All controls are controlled through the control panel. It is easy to touch the screen and operate simply. At the same time, the control panel is small in size, reducing space occupation, and the independent support extension design is far away from the machine, ensuring safety.

For every customer who buys our machine, we will give free parts randomly, and then contact the sales staff to have them.

COMPANY INTRODUCTION

PRODUCT LINE

OUR CUSTOMERS

Our products are sold to many countries and regions all over theworld, and we have established long-term cooperative relations with clients!

PACKAGING & LOGISTICS

FAQ

Q1: How to play order?

A1:Inquiry---Confirm the profile drawings and price ---Confirm Thepl---Arrange the deposit or L/C---Then ok

Q2: How to visit our company?

A2: Fly to Beijing airport: By high speed train from Beijing Nan to Cangzhou Xi(1 hour),then we will pick you up.

Fly to Shanghai Hongqiao airport:By high speed train from Shanghai Hongqiao to Cangzhou Xi(4 hour),then we will pick you up.

Q3: Are you manufacturer or trading company?

A3: We are manufacturer and trading company .

Q4: Do you provide installing and training overseas?

A4: Overseas machine install and worker training services are optional.

Q5: How is your after sales support?

A5: We provide technical support on line as well as overseas services by skillful technicians.

Q6: How does your factory do regarding quality control?

A6: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

Q7: How can I trust you that machines pasted testing running before shipping?

A7: (1) We record the testing video for your reference. Or,

(2) We welcome your visit us and test machine by yourself in our factory

Q8: Do you sell only standard machines?

A8: No. Most machines are customized.

Q9: Will you deliver the right goods as ordered? How can I trust you?

A9: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided).