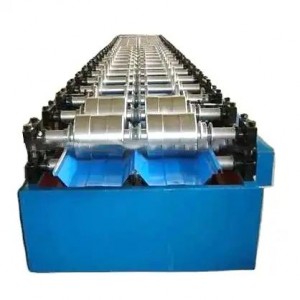

ZKRFM Stand Seam Forming Machine

Color steel arch bending metal roof plate making machine

Product descriptions from the supplier

PRODUCT DESCRIPTION

| Formed Material | PPGI,GI,AI | Thickness:0.3-0.8 mm | |

| Decoiler | Hydraulic decoiler | Manual decoiler(will give you as free) | |

| Main body | Roller station | 9-14rows(As your requirement) | |

| Diameter of shaft | 75mm solid shaft | ||

| Material of rollers | 45#, hard chrome plated on the surface | ||

| Machine body frame | 300H steel | ||

| Drive | Double Chain transmission | ||

| Dimension(L*W*H) | 7500*1300*1500mm | ||

| Weight | About 4000KG | ||

| Cutter | Automatic | cr12mov material, no scratches, no deformation | |

| Power | Main Power | 3KW+3KW or As your requirement | |

| Voltage | 380V 50Hz 3Phase | As your requirement | |

| Control system | Electric Box | Customized(famous brand) | |

| Language | English(Support multiple languages) | ||

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | ||

| Forming Speed | 8-12 m/min | The speed depends on the shape of the tile and the thickness of the material. | |

standing seam roofing machine

The advantages of Standing Seam Roofing Panel Roll Forming Machine Portable Full Automatic are as follows:

1.Low cost, light weight but high strength, short building period, and re-cycle use

2.can produceKALZIP,LYSAGHT,BEMO,KINGSPAN style Standing Seam Roof Panel

3.Easy operation, low maintenance cost

Standing seam roof panel machine rollers:

Rollers manufactured from high quality 40Cr steel, CNC lathes, Heat Treatment.with black treatment or Hard-Chrome Coating for

options. Body frame made from 350# H type steel by welding.

Introducing our Standing Seam Roofing Roll Forming Machine, a cutting-edge, high-performance solution for the precise and efficient production of Standing Seam Roofing Sheets. This state-of-the-art roll forming machine is designed to meet the construction industry’s growing demand for durable and aesthetically pleasing roofing solutions.

Our standing seam shingle roll forming machines are manufactured with quality and reliability in mind, ensuring consistency and accuracy in the production of standing seam shingles. Equipped with advanced technology and features, the machine is easy to operate and maintain, making it ideal for both small and large production facilities.

This roll forming machine utilizes a series of roll forming stations to gradually form rolls of metal into standing seam roof panels. The process is automated and precise, resulting in panels with consistent dimensions and contours. The machine can handle various types of materials, including steel, aluminum and copper, allowing for production versatility and meeting specific project requirements.

The unique design of our standing seam roofing roll forming machines allows for quick tool changes, minimizing downtime and maximizing productivity. This flexibility allows operators to efficiently switch between different panel profiles and sizes, making it suitable for a variety of roofing projects.

In addition to performance and versatility, our roll forming machines prioritize operator safety and convenience. The machine is equipped with safety guards and sensors to prevent accidents and protect operators during operation. User-friendly interface and controls allow operators to easily monitor the production process and make adjustments as needed.

Focused on durability and longevity, our standing seam roofing roll forming machines are built with high-quality materials and components. This ensures reliable and consistent performance, reducing the need for frequent repairs and maintenance. The machine is also designed to minimize material waste, contributing to cost savings and environmental sustainability.

Our standing seam roofing roll forming machines are backed by an experienced team of engineers and technical support staff, providing comprehensive training, installation and after-sales service. This commitment to customer satisfaction ensures that our customers are able to maximize the potential of their roll forming machines and achieve outstanding results in roof panel production.

All in all, our standing seam shingle roll forming machines are the top solution for manufacturing high quality standing seam shingles. With its advanced technology, ease of use and durability, this roll forming machine is a valuable asset to any shingle production facility. Experience the difference with our standing seam roofing roll forming machines and take your roofing projects to the next level.

COMPANY INTRODUCTION

PRODUCT LINE

OUR CUSTOMERS

FAQ

Q1: How to play order?

A1:Inquiry---Confirm the profile drawings and price ---Confirm Thepl---Arrange the deposit or L/C---Then ok

Q2: How to visit our company?

A2: Fly to Beijing airport: By high speed train from Beijing Nan to Cangzhou Xi(1 hour),then we will pick you up.

Fly to Shanghai Hongqiao airport:By high speed train from Shanghai Hongqiao to Cangzhou Xi(4 hour),then we will pick you up.

Q3: Are you manufacturer or trading company?

A3: We are manufacturer and trading company .

Q4: Do you provide installing and training overseas?

A4: Overseas machine install and worker training services are optional.

Q5: How is your after sales support?

A5: We provide technical support on line as well as overseas services by skillful technicians.

Q6: How does your factory do regarding quality control?

A6: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

Q7: How can I trust you that machines pasted testing running before shipping?

A7: (1) We record the testing video for your reference. Or,

(2) We welcome your visit us and test machine by yourself in our factory

Q8: Do you sell only standard machines?

A8: No.Most machines are customized.

Q9: Will you deliver the right goods as ordered? How can I trust you?

A9: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided).