ZKRFM Corrugated Roof Roll Forming Machine Corrugated Forming Machine Corrugated Metal Sheet Machine

PRODUCT DESCRIPTION OF corrugated wall panel roll forming machine

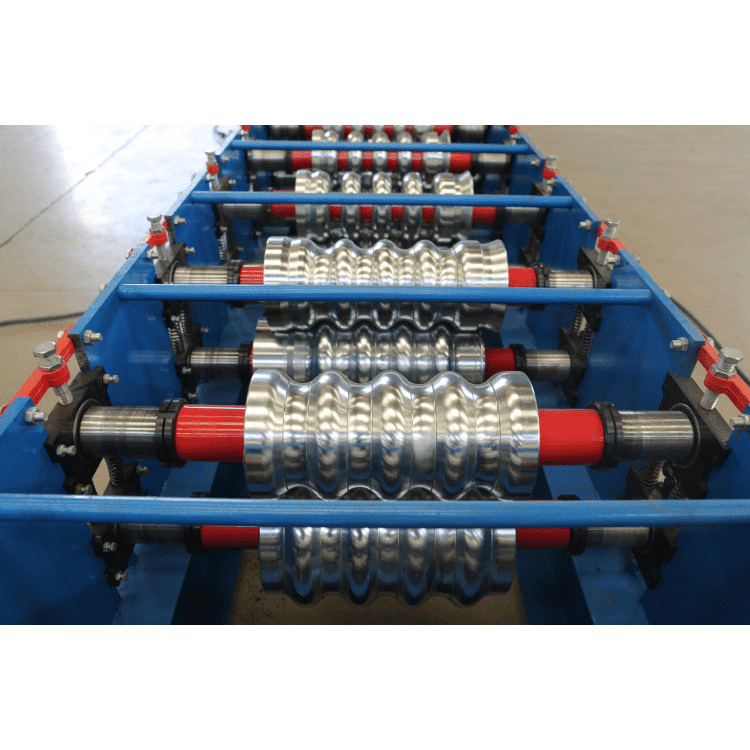

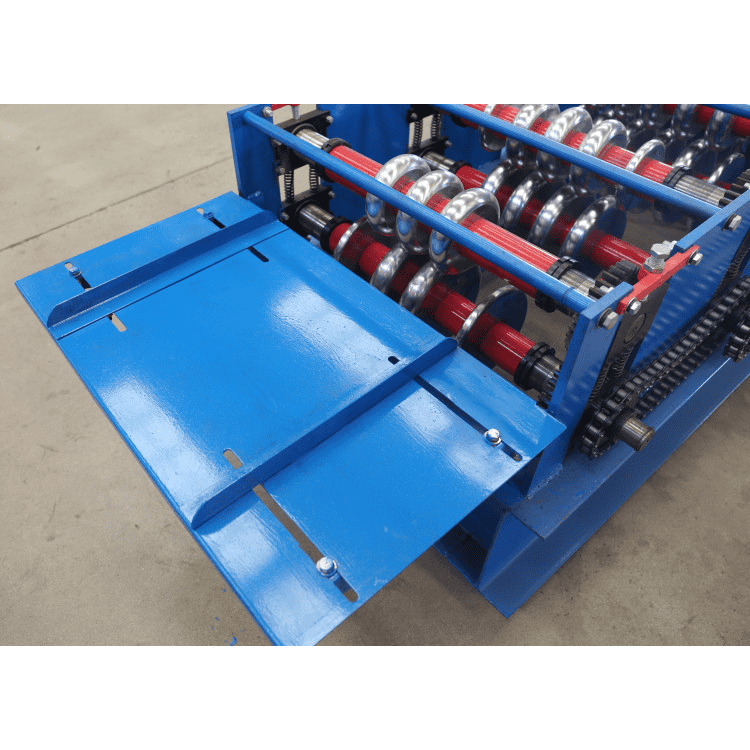

A corrugated wall panel roll forming machine is a specialized piece of equipment used in the construction industry to create corrugated metal wall panels. This machine takes flat metal coils and shapes them into corrugated profiles, which are commonly used for exterior cladding and siding on buildings. The roll forming process involves a series of forming stations to create the desired corrugated pattern on the metal sheets. Corrugated wall panel roll forming machines are essential for producing durable and visually appealing wall cladding materials, offering efficiency and precision in the manufacturing process.

| Formed Material | PPGI,GI,AI | Thickness:0.3-0.7mm |

| Decoiler | Hydraulic decoiler | Manual decoiler(will give you as free) |

| Mai corrugated wall panel roll forming machine n body | Roller station | 24rows(As your requirement) |

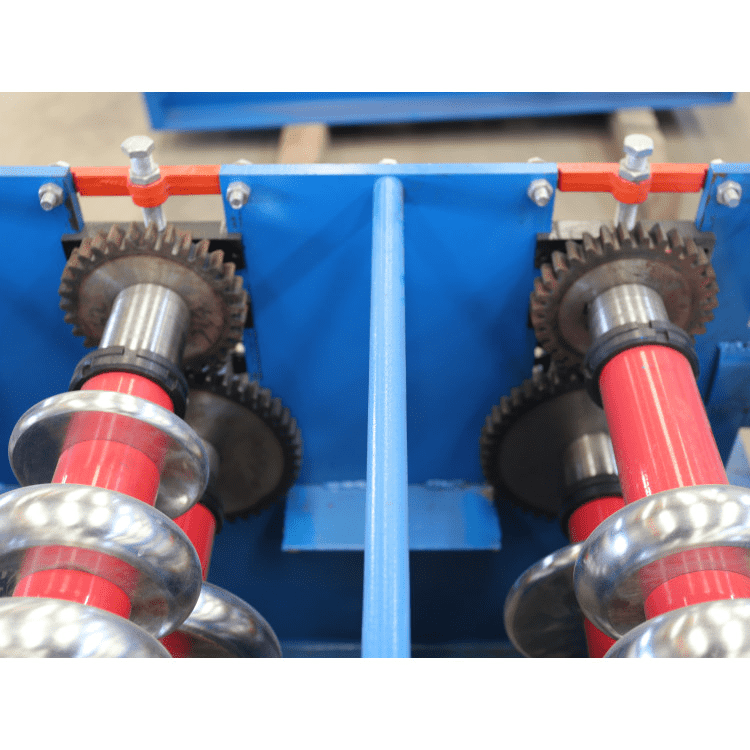

| Diameter of shaft | 70mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | 350 H steel | |

| Drive | one Chain transmission | |

| Dimension(L*W*H) | 10*1.0*1.4 m | |

| Weight | 3.5T | |

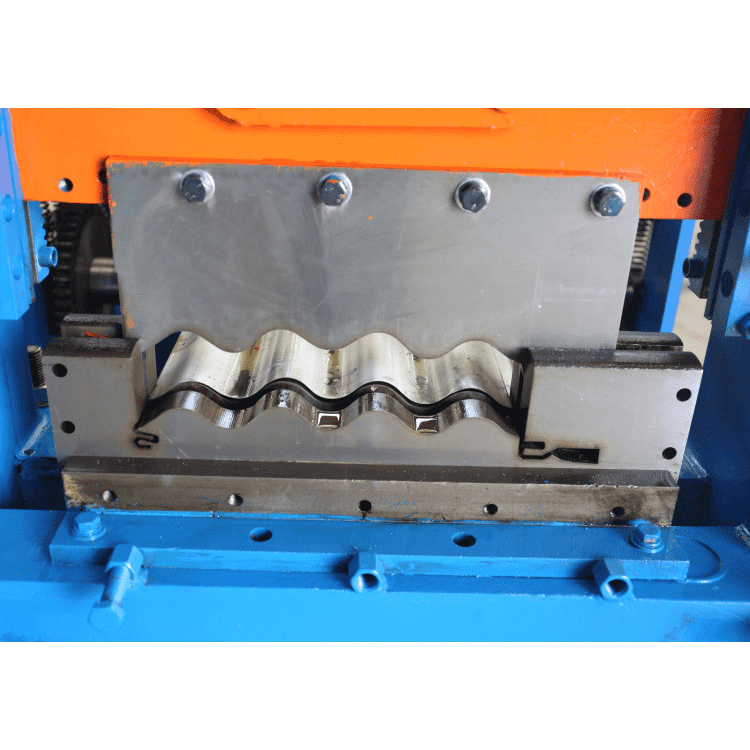

| Cutter | Automatic | cr12mov material, no scratches, no deformation |

| Power | Main Power | 5.5 kw |

| Voltage | 380V 50Hz 3Phase | As your requirement |

| corrugated wall panel roll forming machine Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| Forming Speed | 12-18m / min | The speed depends on the shape of the tile and the thickness of the material. |

COMPANY INTRODUCTION OF corrugated wall panel roll forming machine

PRODUCT LINE OF corrugated wall panel roll forming machine

OUR CUSTOMERS OF corrugated wall panel roll forming machine

Our products are sold to many countries and regions all over theworld, and we have established long-term cooperative relations with clients!

PACKAGING & LOGISTICS OF corrugated wall panel roll forming machine

FAQ

Q1: How to play order?

A1:Inquiry---Confirm the profile drawings and price ---Confirm Thepl---Arrange the deposit or L/C---Then ok

Q2: How to visit our company?

A2: Fly to Beijing airport: By high speed train from Beijing Nan to Cangzhou Xi(1 hour),then we will pick you up.

Fly to Shanghai Hongqiao airport:By high speed train from Shanghai Hongqiao to Cangzhou Xi(4 hour),then we will pick you up.

Q3: Are you manufacturer or trading company?

A3: We are manufacturer and trading company .

Q4: Do you provide installing and training overseas?

A4: Overseas machine install and worker training services are optional.

Q5: How is your after sales support?

A5: We provide technical support on line as well as overseas services by skillful technicians.

Q6: How does your factory do regarding quality control?

A6: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

Q7: How can I trust you that machines pasted testing running before shipping?

A7: (1) We record the testing video for your reference. Or,

(2) We welcome your visit us and test machine by yourself in our factory

Q8: Do you sell only standard machines?

A8: No. Most machines are customized.

Q9: Will you deliver the right goods as ordered? How can I trust you?

A9: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided).