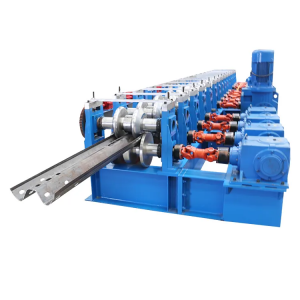

Zk Highway W Beam Guardrail Roll Forming Machine with ISO 9001 Quality Certificate

Maximizing Efficiency and Accuracy with a Highway Roll Forming Machine

When it comes to the construction of highways and roadways, efficiency and accuracy are key factors in ensuring a smooth and safe transportation system. One of the most essential pieces of equipment in this process is a highway roll forming machine. This innovative machine plays a vital role in producing high-quality and precise shapes for guardrails, crash barriers, and other essential components of a roadway system.

Highway roll forming machines are designed to efficiently manufacture long lengths of metal profiles or panels with consistent shapes and dimensions. This process involves feeding a metal coil through a series of roller dies, which gradually forms the material into the desired shape. The result is a finished product that is not only durable and strong but also highly uniform and aesthetically pleasing.

One of the key benefits of using a highway roll forming machine is its ability to produce large quantities of custom-formed components with minimal waste. This not only reduces material costs but also helps to streamline the production process, ultimately saving time and labor. Additionally, the precision and uniformity achieved through roll forming technology ensure that the finished products meet strict regulatory standards and perform effectively in real-world applications.

Furthermore, the flexibility of highway roll forming machines allows for the creation of a wide variety of profiles and shapes to meet the specific requirements of different roadway projects. Whether it’s a complex guardrail design or a simple crash barrier, a roll forming machine can be easily reconfigured to produce the necessary components with precision and speed. This adaptability makes it an ideal solution for both large-scale highway construction as well as smaller, more specialized road improvement projects.

In addition to its manufacturing capabilities, a highway roll forming machine also offers benefits in terms of safety and durability. The finished components produced by this machine are engineered to withstand the harsh conditions of outdoor environments, ensuring that they provide long-lasting protection and stability for motorists and pedestrians alike. Moreover, the use of high-quality materials and precise forming techniques results in a product that is structurally sound and reliable, reducing the need for frequent maintenance and replacement.

From a cost perspective, investing in a highway roll forming machine can result in significant long-term savings for construction companies and government agencies. By bringing the manufacturing process in-house, there is greater control over production schedules, quality assurance, and overall project timelines. This can lead to reduced lead times, lower production costs, and ultimately, a more efficient and cost-effective construction process. Furthermore, the ability to quickly adapt to changing design requirements and produce custom components on-demand can lead to improved project management and client satisfaction.

In conclusion, a highway roll forming machine is a crucial tool for modern roadway construction and improvement projects. Its ability to efficiently produce high-quality, custom-formed components not only increases productivity and lowers production costs but also ensures that the finished products meet stringent regulatory standards and perform effectively in real-world applications. By investing in this advanced technology, construction companies and government agencies can maximize efficiency and accuracy, leading to safer and more reliable roadway systems for communities across the globe.