The Ultimate Guide to JCH Roll Forming Machines

If you are in the market for a high-quality roll forming machine, look no further than the JCH roll forming machine. With its advanced technology and innovative design, the JCH roll forming machine is the perfect solution for all your metal forming needs.

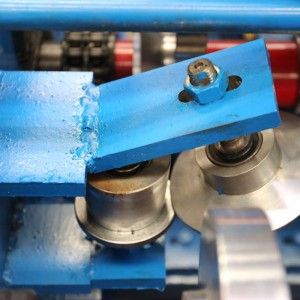

What sets JCH cold roll forming machines apart from the competition is their precision engineering and unparalleled performance. The machine's ability to produce high-quality and precise metal products with ease makes it the first choice of fabricators and fabricators around the world.

One of the main features of JCH roll forming machines is their versatility. Whether you need to produce roof panels, wall cladding or custom profiles, this machine can meet your needs. Its modular design allows for quick and easy tool changes, making it an ideal solution for low-volume production or quick turnaround times.

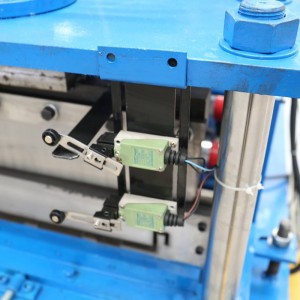

In addition to their versatility, JCH cold roll forming machines offer a high level of automation. This means you can significantly reduce labor costs and increase the efficiency of your production process. With automated controls and precision measurement systems, you can trust that every product that comes off the line will meet your exact specifications.

Another advantage of JCH roll forming machines is their durability and reliability. The machine is built with high-quality materials and components and is designed to withstand harsh production environments. With proper care and maintenance, you can expect your JCH roll forming machine to provide consistent performance for years to come.

In terms of safety, JCH roll forming machines are designed with operator protection in mind. From safety guards to emergency stop systems, you can rest assured knowing your operators are protected while the machine is running.

In addition, JCH roll forming machines are backed by a dedicated support team. From installation and training to maintenance and troubleshooting, you can rely on the expertise of the JCH team to keep your machines running smoothly and efficiently.

All in all, JCH roll forming machines are the ultimate solution for builders and fabricators who need a high-quality, reliable metal forming machine. Its precision engineering, versatility, automation, durability and safety features make it an outstanding choice in the market. Whether you are looking to increase production capacity, improve product quality or reduce labor costs, a JCH roll forming machine is the perfect investment for your business.

| ITEM | SPECIFICATION | |

|

Material |

Raw material | PPGI/GI/PPGL/GL |

| Material thickness | 0.4-1mm | |

| Feeding width/coil width | 1000mm | |

|

Machine |

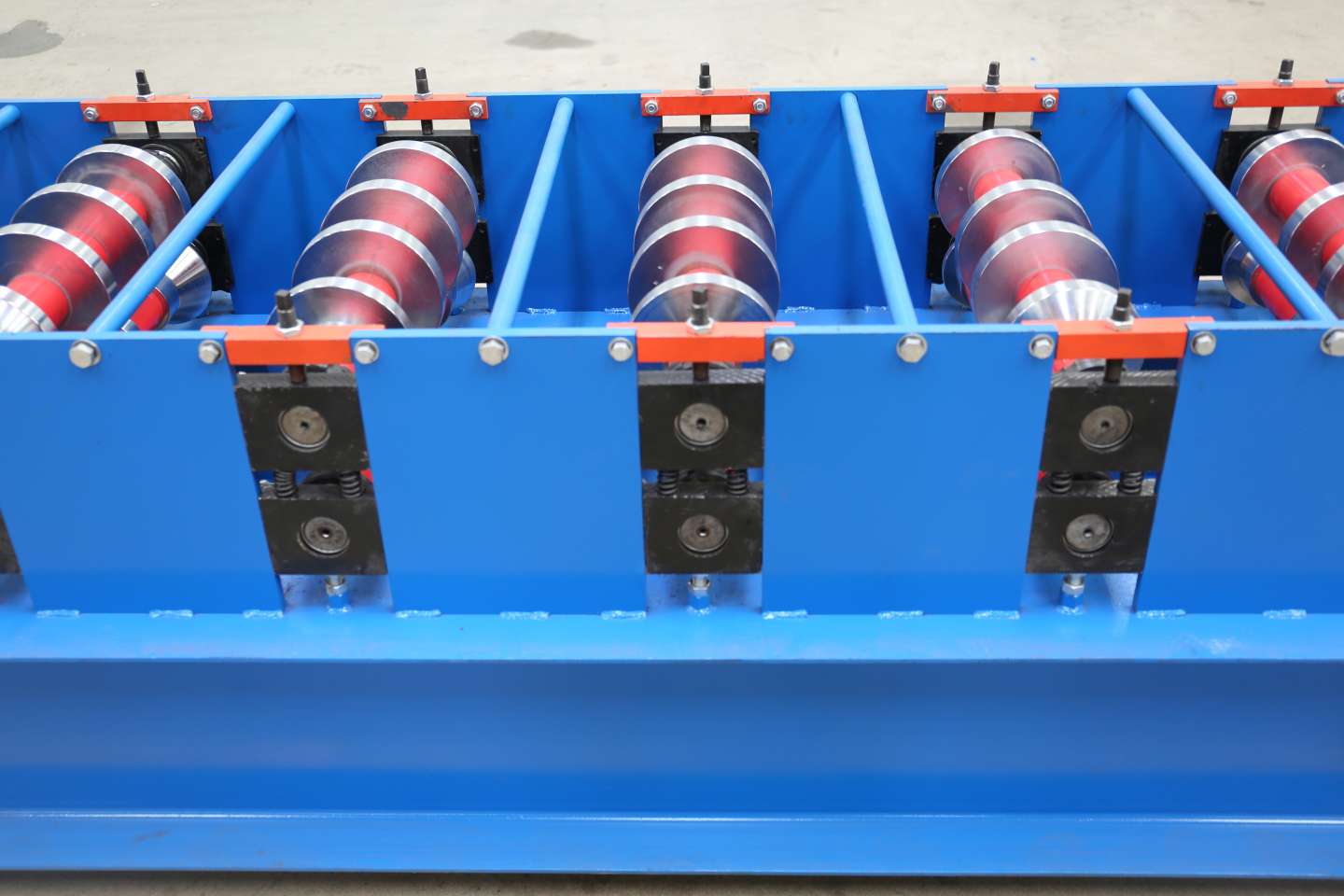

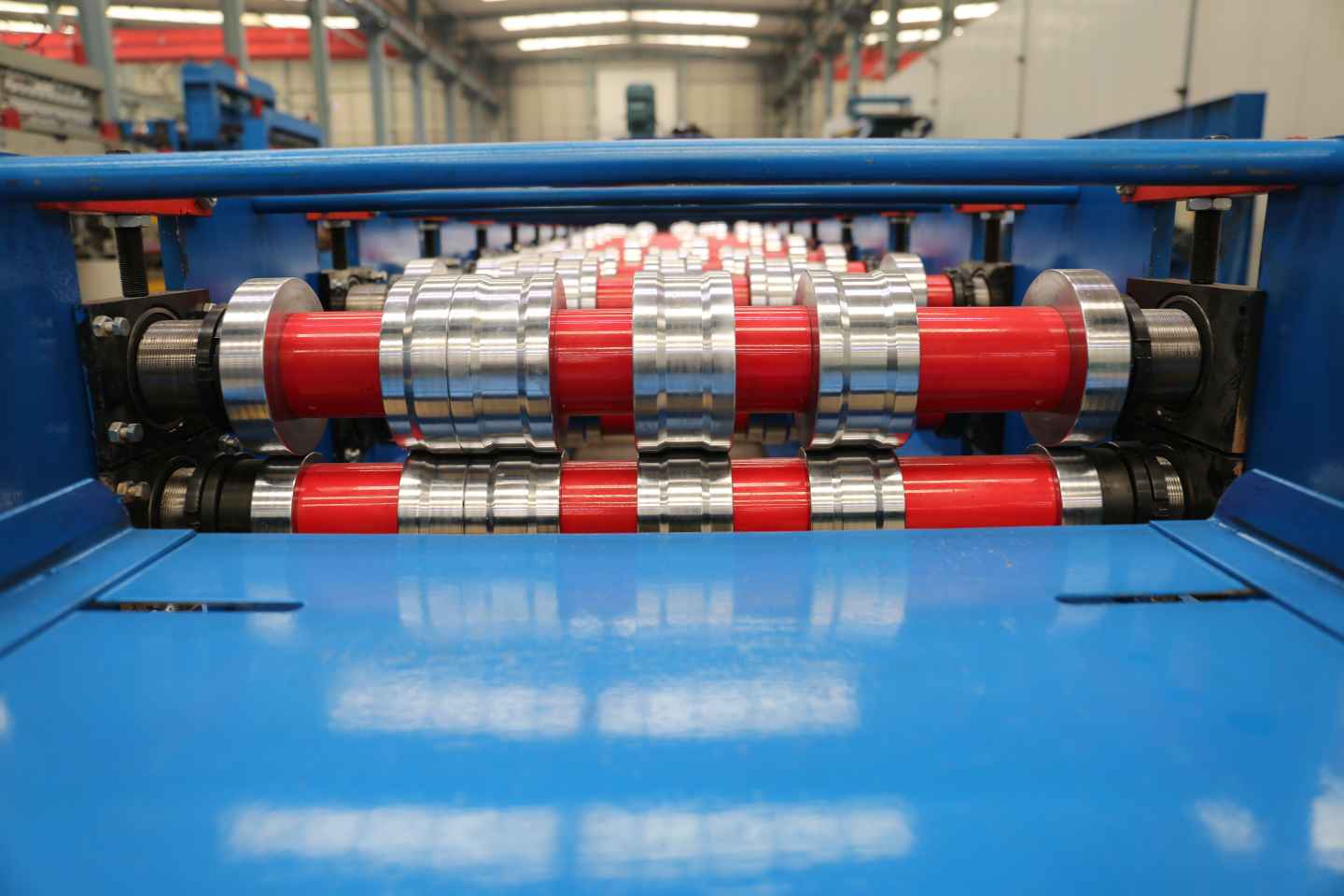

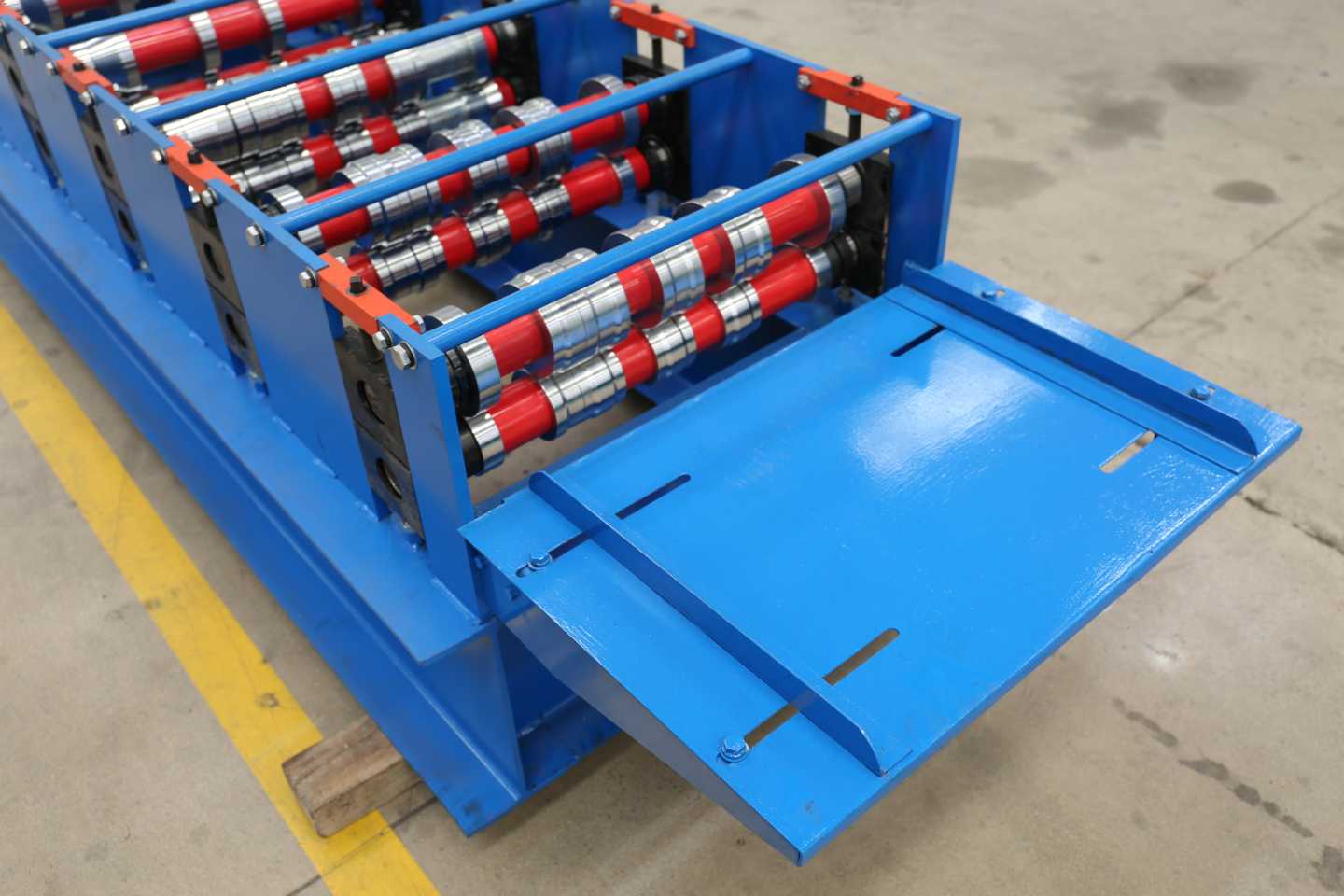

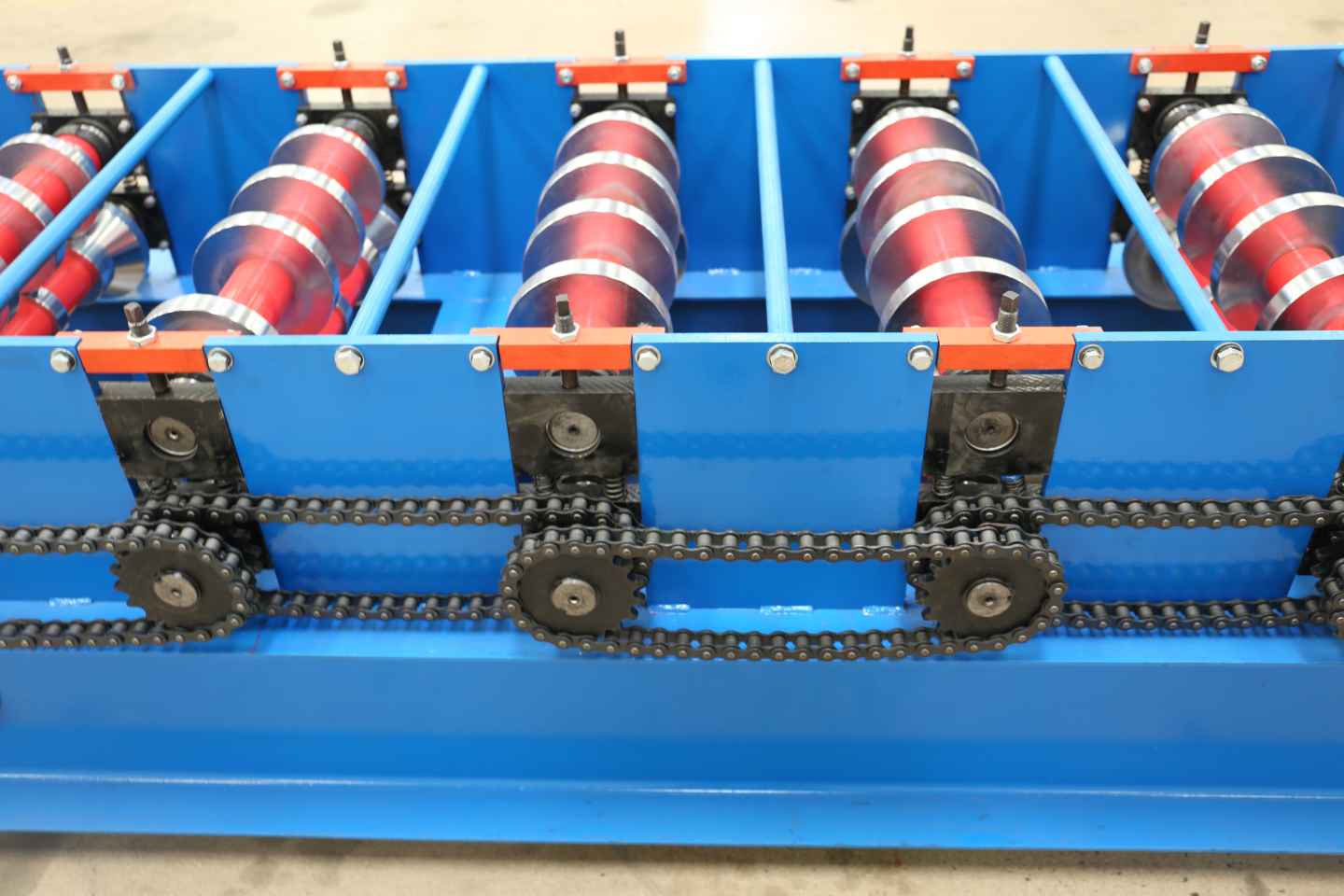

Roller stations | 20 stations |

| Shaft diameter | 75mm | |

| Shafte material | 45# steel with Hard chrome plating | |

| Roller material | 45# steel with hard chrome coating | |

| dimension | 8600*1500*1300mm | |

| weight | 5500kg | |

| color | customize | |

| Forming speed | 0-20m/min | |

| Driving mode | Motor drive, chain drive | |

| Middle plate thickness | 16mm | |

| Main frame | 350mm H-Beam | |

|

Cutter |

Cutter material | Cr12 with hard treatment |

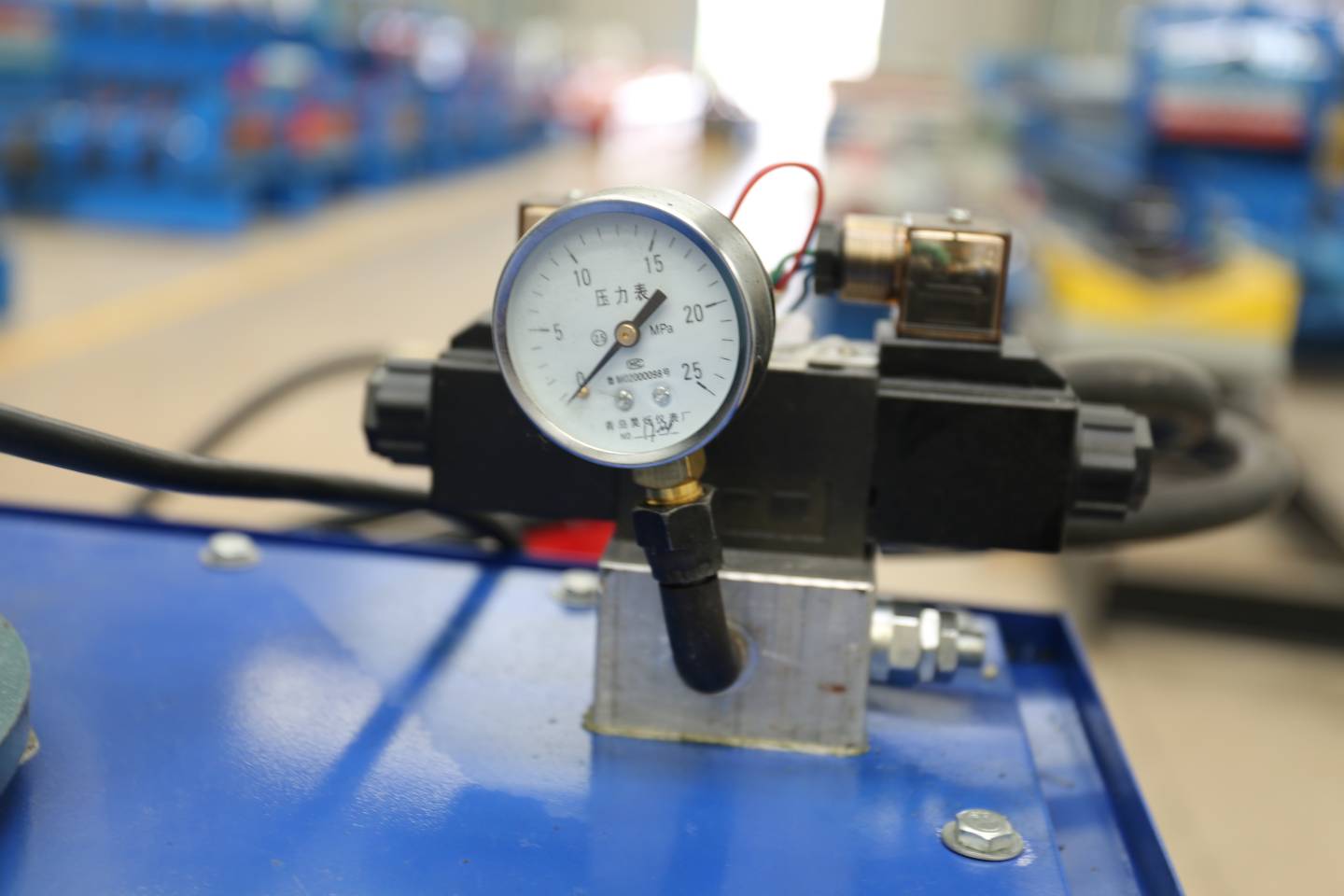

| Cutting method | Hydraulic cutting | |

| Cutting Tolerance | ± 1mm | |

| Main power | 5.5kw*2 | |

| Pump power | 4kw | |

| voltage | 400v+-5%,50Hz,3phrase(as the customer’s requests) | |

| PLC brand | Delta PLC | |

|

Control system |

Language | English ,Chinese |

| Operation | Manual |