During the roll forming process, the plate is evenly stressed, and the surface is not prone to scratches, wrinkles or deformation. The formed curtain pieces are flat and beautiful, reducing the appearance defects caused by manual operation in traditional processes.

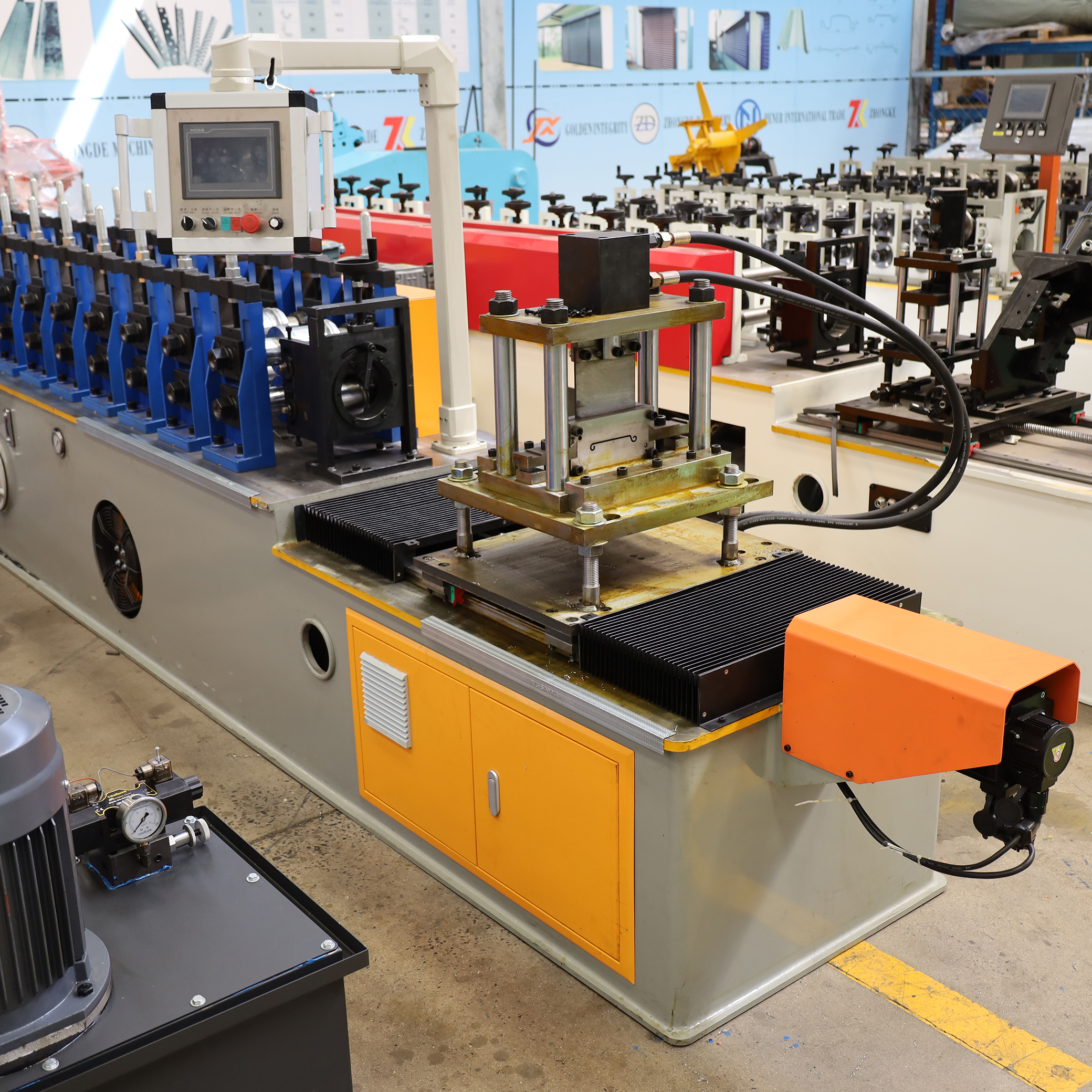

The main frame is welded or cast with high-strength steel, and with heavy-duty bearings and gear transmission systems, it can withstand the greater stress during the roll forming process, suitable for 24-hour continuous production, and the equipment life can reach more than 10 years.

The rolling door forming machine has become a key equipment for rolling door manufacturers to enhance their competitiveness through its core advantages such as efficient automation, high-precision production, flexible changeover, durability and low consumption. For small and medium-sized enterprises, they can choose cost-effective single-machine equipment; large enterprises can configure fully automated production lines to achieve large-scale and customized production to meet diverse market needs.

Post time: May-30-2025